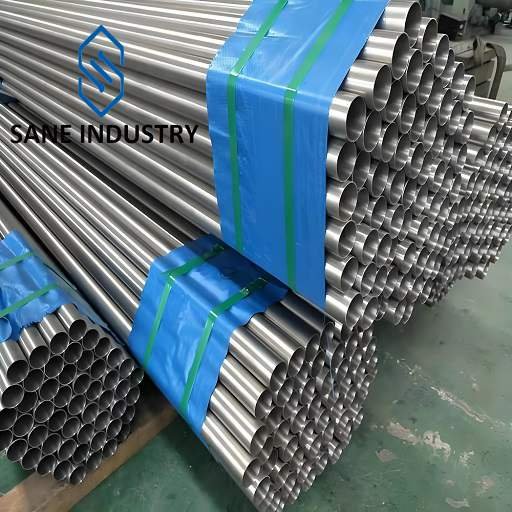

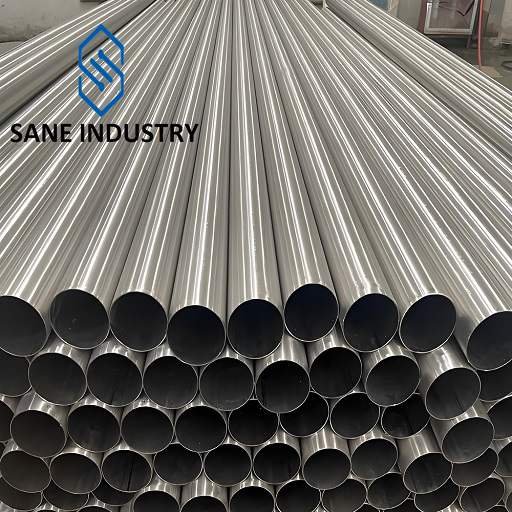

What is a Titanium Pipe

A titanium pipe(also known as titanium tube) is a tubular structure manufactured from titanium or titanium alloys, designed to transport fluids, gases, or other materials under specific conditions. Renowned for its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility, titanium piping is widely used in industries where performance under extreme environments is critical.

Titanium Pipe Types

- Based on Manufacturing Process

- Seamless Titanium Pipes:

Produced through extrusion or rotary piercing, these pipes lack welded seams, making them ideal for high-pressure, high-temperature applications such as aerospace hydraulics or chemical reactors. - Welded Titanium Pipes:

Formed by rolling titanium sheets into cylindrical shapes and welding the seams. Cost-effective for low-pressure systems like water distribution or ventilation.

- Seamless Titanium Pipes:

- Based on Material Grade

- Commercially Pure (CP) Titanium Pipes (Grades 1–4):

Unalloyed titanium pipes with excellent corrosion resistance. Grade 2 is widely used in marine and desalination systems. - Titanium Alloy Pipes (e.g., Grade 5/Ti-6Al-4V):

Enhanced strength and heat resistance due to aluminum and vanadium additives. Common in aerospace structural components and medical implants.

- Commercially Pure (CP) Titanium Pipes (Grades 1–4):

- Based on Cross-Sectional Shape

- Round Titanium Pipes:

Standard cylindrical shape for general fluid or gas transport in industrial pipelines. - Oval/Flattened Titanium Pipes:

Used in heat exchangers or confined spaces where compact design is critical. - Rectangular/Square Titanium Pipes:

Employed in architectural frameworks or specialty equipment requiring rigidity. - Spiral-Welded Titanium Pipes:

Fabricated by helically welding strips, suited for large-diameter applications like seawater intake systems.

- Round Titanium Pipes:

What are the advantages of Titanium Pipes

Superior Corrosion Resistance

Resists saltwater, acids, chlorides, and industrial chemicals, outperforming stainless steel in harsh environments like offshore platforms or chemical plants.High Strength-to-Weight Ratio

Combines steel-like strength with 45% less weight, ideal for aerospace, automotive, and portable systems requiring lightweight durability.Extreme Temperature Tolerance

Maintains integrity from cryogenic (-250°C) to high-heat (600°C) conditions, suitable for LNG systems or high-temperature reactors.Biocompatibility

Non-toxic and compatible with human tissue, widely used in medical implants, surgical tools, and pharmaceutical equipment.Non-Magnetic Properties

Electromagnetic neutrality ensures compatibility with MRI machines, submarines, and sensitive electronic environments.Long Service Life & Low Maintenance

Resists pitting, erosion, and degradation, reducing replacement costs and downtime in corrosive or abrasive settings.Eco-Friendly & Recyclable

Environmentally inert and fully recyclable, aligning with sustainable manufacturing practices.

What are the disadvantages of Titanium Pipes

High Cost

Titanium is expensive to extract, refine, and process, making titanium pipes significantly pricier than steel or aluminum alternatives.Machining Challenges

Requires specialized tools and slow cutting speeds due to titanium’s hardness and abrasiveness, increasing fabrication costs.Welding Complexity

Sensitive to contamination during welding; demands inert gas shielding (e.g., argon) and skilled labor to avoid brittleness.Thermal Expansion Mismatch

Higher thermal expansion coefficient than steel may cause stress in systems with fluctuating temperatures.Limited Large-Size Availability

Producing large-diameter or thick-walled titanium pipes is technically challenging and cost-prohibitive.Low Elastic Modulus

Less flexible than steel, making titanium pipes less suited for applications requiring bending or vibration absorption.Galvanic Corrosion Risk

When coupled with dissimilar metals in conductive environments (e.g., seawater), titanium can accelerate corrosion in adjacent materials.

How are Titanium Pipes made

- Material Preparation

- Titanium Sponge Conversion: Raw titanium sponge (produced via the Kroll process) is melted in a vacuum arc furnace to form ingots.

- Ingot Processing: Ingots are forged or rolled into billets or slabs for further shaping.

- Seamless Pipe Production

- Extrusion: Billets are heated and forced through a die to create hollow tubes.

- Rotary Piercing: A hot billet is pierced with a mandrel to form a seamless pipe, followed by elongation and sizing.

- Cold Rolling/Drawing: Seamless pipes are further refined for precision dimensions and surface finish.

- Welded Pipe Production

- Sheet Rolling: Titanium plates or sheets are rolled into cylindrical shapes.

- Welding: Edges are joined using TIG (Tungsten Inert Gas) or laser welding under argon shielding to prevent contamination.

- Annealing: Post-weld heat treatment removes residual stresses and enhances ductility.

- Finishing Processes

- Surface Treatment: Pipes undergo pickling (acid cleaning) to remove oxides and passivation to improve corrosion resistance.

- Precision Machining: Ultrasonic testing, grinding, or polishing is applied for medical or aerospace-grade pipes.

- Quality Assurance

- Non-destructive testing (ultrasonic, X-ray) ensures integrity.

- Compliance with standards like ASTM B337 (seamless) or ASTM B862 (welded).

What is a titanium pipe used for

- Chemical Processing

Handle aggressive acids, chlorides, and solvents in reactors, heat exchangers, and piping systems exposed to corrosive media. - Offshore & Marine Engineering

Resist saltwater corrosion in desalination plants, shipboard cooling systems, and subsea oil/gas pipelines. - Aerospace & Aviation

Lightweight fuel lines, hydraulic systems, and engine components for aircraft and spacecraft. - Medical Applications

Biocompatible tubing for surgical instruments, implantable devices, and pharmaceutical production equipment. - Energy Sector

Withstand high temperatures and radiation in nuclear power condensers, geothermal steam transport, and hydrogen storage systems. - Oil & Gas Exploration

Durable piping for sour (high-sulfur) well environments, deep-sea drilling rigs, and refinery processes. - Environmental Technology

Used in flue gas scrubbers, wastewater treatment, and pollution control systems due to acid resistance. - High-Performance Sports

Ultralight frames for bicycles, motorsport exhausts, and marine racing components.

Our Titanium Pipe Sizes and Materials

| Outside Diameter | 6 to 273 mm | 1/8” to 10” NPS |

| Wall Thickness | 0.5 to 22 mm | 0.01” to 0.9” |

| Length | Customized | |

| Type of End | Plain Ends, Beveled Ends | |

| Material | Standard: ASTM B337/ASME SB337, ASTM B338/ASME SB338, ASTM B861/ASME SB861, ASTM B862/ASME SB862, etc. Grade: GR1, GR2, GR3, GR5, GR7, GR9, GR12, GR23, any other. | |

For other customized requirements, please contact us. We can also provide titanium tube bending services.

What is the Titanium Pipe Price

Please contact our sales manager Allen@sanesteel.com

Why Choose Us

- a 16-year titanium tube supplier in china supplier. We are experts.

- solutions for all your needs

- the highest product quality

- the low lead times

- excellent customer service