Your Trusted Finned Tube Manufacturer & Supplier Worldwide

We specialize in manufacturing high-efficiency, corrosion-resistant finned tubes with custom specifications, material options, and full industry certifications. Over 15 years of experience serving global industrial clients.

Our Premium Finned Tube Products & Solutions

We offer a full range of high-performance industrial finned tubes and custom solutions to meet the diverse needs of petrochemical, power generation, HVAC, and other industrial applications.

Why Choose SANE Industry As Your Finned Tube Manufacturer

All our finned tubes are manufactured with strict quality control, here’s why we’re the trusted choice for 100+ global clients.

Rich Industry Experience

Over 15 years of professional finned tube manufacturing experience, serving 100+ clients across 30+ countries in petrochemical, power, HVAC industries.

Industry-Leading Quality & Certifications

ISO 9001, CE, ASME certified production, strict quality inspection from raw material to finished products, 100% NDT before delivery.

Full Customization Capability

Custom fin pitch, thickness, material, and size to match your exact application requirements, no MOQ limit for regular specifications.

Factory Direct Pricing

No middleman, direct from our own manufacturing facility, offering the best price-performance ratio for bulk and custom orders.

Advanced Production Technology

State-of-the-art high frequency welding, extrusion, and rolling production lines, ensuring high heat transfer efficiency and consistent product performance.

Our Standardized Finned Tube Manufacturing Process

As a professional finned tube manufacturer with over 15 years of industry experience, we have built a fully controlled, ISO 9001 & ASME certified production process for finned tubes. Every step is strictly executed to ensure our products meet the highest standards of heat transfer efficiency, corrosion resistance and service life for global industrial clients.

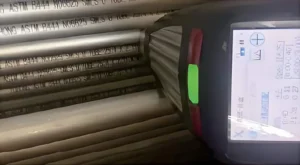

Step 1: Raw Material Inspection & Testing for Finned Tubes

We strictly inspect all incoming raw materials (seamless steel tubes, steel strips, aluminum alloys, etc.) according to ISO 9001 and ASME standards. We conduct full chemical composition analysis, dimension and surface defect inspection to eliminate unqualified raw materials before production, ensuring the basic performance of our finned tubes.

Step 2: Finned Tube Manufacturing

According to your custom specifications, we adopt corresponding finned tube manufacturing processes including high frequency welded finning, extruded finning, helical rolled finning, etc. Our state-of-the-art CNC finned tube production lines ensure precise fin pitch, fin height, and wall thickness control, with zero damage to the base tube during processing.

Step 3: Dimensional & Performance Precision Testing

Our professional QC team conducts 100% full inspection of all finished finned tubes, including fin pitch, fin height, tube outer diameter, wall thickness, straightness and other dimensional parameters, ensuring all products fully meet your drawing and specification requirements.

Step 4: Leakage & Pressure Resistance Testing

This is the core quality control step for our finned tubes. We conduct hydrostatic pressure testing for every product, with test pressure up to 1.5 times the working pressure, to ensure zero leakage and stable operation in heat exchanger, boiler and other high-pressure equipment.

Step 5: Surface Treatment & Anti-Corrosion Coating

We offer a full range of surface treatment options including galvanizing, painting, and anti-rust oil, according to your application scenarios (petrochemical, power generation, offshore, etc.). All treatments strictly comply with industry anti-corrosion standards, avoiding rust and oxidation during long-term use.

Step 6: Customized Packaging & On-Time Delivery

We offer anti-collision, moisture-proof, rust-proof packaging solutions according to your transportation requirements (sea/air/land). We also support custom marking, labeling and packaging specifications, with a mature global logistics system to ensure on-time delivery to your designated location.

Every step of our finned tube manufacturing process is traceable and fully documented. Contact us now to get the custom solution for your project.

Industrial Applications Of Our Finned Tubes

Our high-quality finned tubes are widely used in various industrial sectors that require high-efficiency heat transfer, including:

Finned Tubes for Petrochemical Industry

Our high-temperature and corrosion-resistant finned tubes are custom-built for petrochemical heat exchangers, reboilers and pipeline systems, delivering stable heat transfer performance in harsh acidic and high-pressure refining environments.

Finned Tubes for Power Generation & Power Plants

We manufacture heavy-duty boiler finned tubes and economizer fin tubes for thermal power, waste heat recovery and renewable power generation plants, ensuring long service life under continuous high-temperature operation.

Finned Tubes for HVAC & Refrigeration

Our high-efficiency HVAC finned tubes and refrigeration fin tubes are ideal for air conditioning units, chillers and heat pump systems, maximizing heat exchange efficiency while reducing energy consumption for commercial and industrial HVAC projects.

Finned Tubes for Oil & Gas Industry

We supply rugged offshore and onshore oil and gas finned tubes for gas processing units, heat recovery systems and pipeline heating applications, with anti-corrosion coatings to withstand harsh offshore marine environments.

Marine Grade Finned Tubes for Marine & Offshore Applications

Our DNV-certified marine grade finned tubes are designed for shipboard HVAC systems, engine cooling units and offshore platform heat exchangers, with superior salt spray and corrosion resistance for marine environments.

Sanitary Food Grade Finned Tubes for Food & Beverage Processing

We produce 304/316L stainless steel sanitary finned tubes for food and beverage processing, including pasteurization systems, drying equipment and heat exchangers, meeting strict FDA food safety standards.

Success Cases & Client Testimonials of Our Finned Tubes

As a professional finned tube manufacturer with over 15 years of experience, we have completed 100+ projects for industrial clients across 30+ countries. Below are our representative cases and real feedback from global partners.

High Efficiency Finned Tube for Waste Heat Recovery System in Portugal

Client Pain Point: Needed high-temperature resistant finned tubes for waste heat recovery system, requiring strict EN standard compliance.

Our Solution: Customized EN10216-2 P235GH carbon steel helical finned tubes with full dimensional testing.

Project Result: Heat transfer efficiency increased by 22%, 12 days ahead of scheduled delivery.

Corrosion Resistant Finned Tubes for Refineries in Germany

Client Pain Point: Needed corrosion-resistant finned tubes for a refinery hydrocracking unit, facing severe sulfidic and acidic medium corrosion, requiring full ASTM and EN standard compliance.

Our Solution: Customized 347 stainless steel high frequency welded finned tubes with optimized fin pitch design to reduce dust accumulation, with 100% weld bonding rate inspection.

Project Result: Single continuous operation cycle extended from 6 months to 18 months, annual maintenance cost reduced by 60%.

Corrosion Resistant Finned Tubes for Refineries in Germany

Client Pain Point: Needed corrosion-resistant finned tubes for a refinery hydrocracking unit, facing severe sulfidic and acidic medium corrosion, requiring full ASTM and EN standard compliance.

Our Solution: Customized 347 stainless steel high frequency welded finned tubes with optimized fin pitch design to reduce dust accumulation, with 100% weld bonding rate inspection.

Project Result: Single continuous operation cycle extended from 6 months to 18 months, annual maintenance cost reduced by 60%.