What is an Intermediate Tube Support

An Intermediate Tube Support (ITS) is a specialized structural component used to stabilize and secure tubes or tube bundles within equipment such as heat exchangers, boilers, condensers, or nuclear reactors. Unlike primary supports (e.g., tube sheets or end anchors), ITS is installed at intermediate points along the length of tubes to prevent excessive vibration, sagging, or misalignment caused by thermal expansion, fluid flow forces, or mechanical loads.

Structure and Design of Intermediate Tube Supports

- Material: Typically made of corrosion-resistant metals (carbon steel, stainless steel, Inconel) or composites, depending on temperature, pressure, and chemical exposure.

- Geometry:

- Baffles/Grids: Perforated plates or grids that hold tubes in a fixed pattern while allowing fluid flow (common in shell-and-tube heat exchangers).

- Anti-Vibration Bars (AVBs): Metal strips welded or clamped between tubes to dampen resonant vibrations.

- Spacer Bars/Rods: Horizontal or vertical bars inserted between tube rows to maintain spacing and alignment.

- Spring-Loaded Clamps: Adjustable supports that accommodate thermal expansion dynamically.

- Mounting: Welded, bolted, or clipped to the equipment shell or casing.

Core Functions of Intermediate Tube Supports

- Vibration Suppression:

- Mitigates flow-induced vibrations (e.g., vortex shedding, turbulence) to prevent tube fatigue, fretting, or failure.

- Alignment Control:

- Maintains uniform tube spacing and parallelism, ensuring efficient heat transfer and fluid dynamics.

- Load Distribution:

- Reduces stress on primary supports (e.g., tube sheets) by sharing mechanical, thermal, and hydraulic loads.

- Thermal Expansion Management:

- Allows controlled axial movement while restricting lateral deflection during temperature fluctuations.

Common Applications of Intermediate Tube Supports

- Shell-and-Tube Heat Exchangers: Stabilizes U-tube or straight-tube bundles, preventing sagging and vibration in high-flow environments.

- Power Plant Boilers: Supports steam/water tubes in high-temperature, high-pressure conditions.

- Nuclear Reactors: Secures fuel rods or coolant channels to prevent vibration-induced damage.

- Condensers: Minimizes tube deflection in large-scale cooling systems.

- Chemical Reactors: Maintains tube integrity in corrosive or erosive media.

Types of Intermediate Tube Supports

- Segmental Baffles:

- Single or double-segmental plates with cutouts for tubes; guide shell-side fluid flow while providing lateral support.

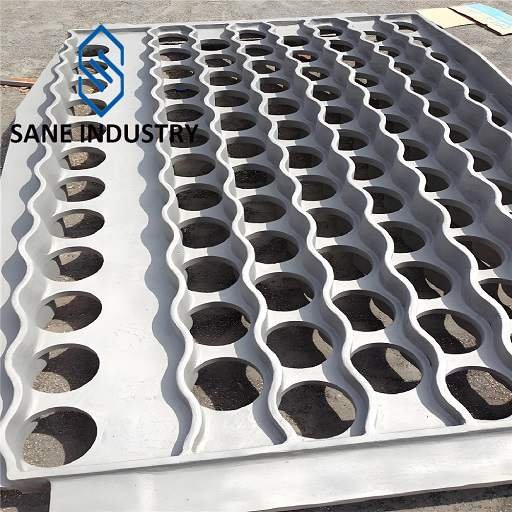

- Orifice Supports:

- Perforated plates with tighter tolerances to restrict tube movement and enhance vibration damping.

- Rodded Grids:

- Grid frameworks with spacer rods between tube rows to maintain pitch and alignment.

- Helical Baffles:

- Spiral-shaped baffles that reduce pressure drop while stabilizing tubes.

- Leaf-Type Supports:

- Flexible metal leaves that absorb vibration energy and allow thermal movement.

Sizes and Materials of Our Intermediate Tube Supports

| Size | As per client’s requirements and drawings | |

| Material Grade | A/SA-216 | WCA, WCB, WCC |

| A/SA-217 | WC1, WC4, WC5, WC6, WC9, WC11, C5, C12, etc. | |

| A/SA-297 | HF, HH, HK, HE, HT, HU, HW, HX, etc. | |

| A/SA-351 | HK30, HK40, HT30, CF3, CF8, CF10, CH8, CG8M, CH10, CH20, CK20, etc. | |

| A/SA-352 | LCA, LCB, LCC, LC1, LC2, LC3, LC4, LC9, etc. | |

| A/SA-389 | C23, C24 | |

| A/SA-447 | Type I, Type II | |

| A/SA-487 | GR1, GR2, GR4, GR6, GR7, GR8, GR12, etc. | |

| A/SA-560 | 50Cr-50Ni, 60Cr-40Ni, 50Cr-50Ni-Cb | |

| A/SA-990 | CK3MCuN, CW-2M, CN3MCu, M35-1, etc. | |

| A/SA-995 | GR1B, GR2A, GR3A, GR4A, GR5A, GR6A, GR7A, etc. | |

For other customized requirements, please contact us.

Comparison with Primary Supports

| Feature | Intermediate Tube Support | Primary Support (e.g., Tube Sheet) |

|---|---|---|

| Location | Mid-span of tubes | Ends of tubes |

| Function | Vibration damping, alignment, load distribution | Anchoring tubes, sealing pressure boundaries |

| Load Handling | Shares dynamic and thermal loads | Bears primary mechanical and pressure loads |

| Design Complexity | Focuses on flexibility and vibration resistance | Requires high structural rigidity and sealing |

Why Choose Us

- 16 years of experience in this industry. We are experts.

- solutions for all your needs

- the highest product quality

- the low lead times

- excellent customer service