What is a Pipe Cap

A pipe cap is a vital piping component used to seal the end of a pipe, preventing the ingress of contaminants, fluids, or debris. Designed to withstand internal pressure, corrosion, and mechanical stress, it ensures system integrity in pipelines, pressure vessels, and industrial equipment.

Pipe Caps Types

- Based on Shape

- Hemispherical Cap: Rounded dome shape for uniform pressure distribution (common in high-pressure systems).

- Flat/Plate Cap: Simple flat-end design for low-pressure or non-critical applications.

- Ellipsoidal Cap: Oval-shaped to reduce stress concentration in specific piping layouts.

- Based on Connection Method

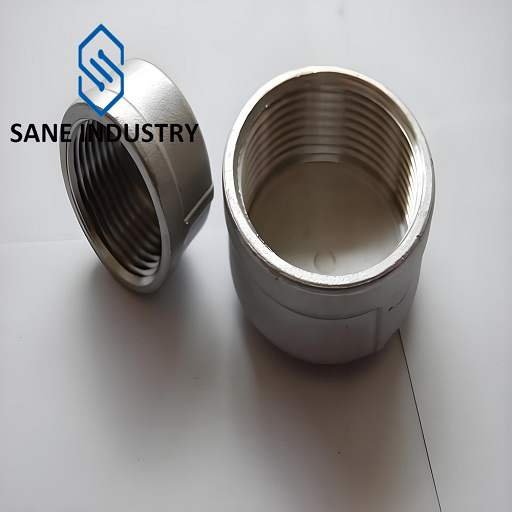

- Threaded Cap: Screws onto external pipe threads (e.g., NPT, BSP).

- Socket Weld Cap: Welded into place for permanent sealing in high-pressure lines.

- Butt Weld Cap: Welded directly to the pipe end, ensuring a robust, leak-proof joint.

- Push-On/Snap Cap: Used in temporary or low-pressure systems (e.g., PVC drainage pipes).

- Based on Material

- Metal Caps: Carbon steel pipe cap, stainless steel pipe cap, alloy steel pipe cap, copper pipe cap(for high-temperature/pressure or corrosive fluids).

- Plastic Caps: PVC, CPVC, HDPE (for chemical resistance in water treatment or sewage systems).

- Composite Caps: Fiberglass-reinforced polymers (used in specialized industrial environments).

What are the advantages of Pipe Caps

Secure Pressure Containment

- Seals pipe ends to prevent leaks in pressurized systems.

Material Versatility

- Available in metals, plastics, or composites to suit corrosive, high-temperature, or lightweight needs.

Corrosion & Contamination Protection

- Shields pipes from environmental damage, debris, and chemical exposure.

Easy Installation/Maintenance

- Options like threaded, snap-on, or welded designs simplify installation and temporary access.

Durability

- Resists wear, thermal stress, and mechanical impact for long-term use.

Cost-Effective Safety

- Prevents accidents, reduces downtime, and extends pipeline lifespan with minimal investment.

Customization

- Adaptable to pipe sizes, shapes (hemispherical, flat), and industry standards (ASME, ASTM).

What are the disadvantages of Pipe Caps

Installation Complexity

- Welded caps require skilled labor and equipment, increasing time and cost.

Material Limitations

- Plastic caps degrade under UV/heat; metal caps corrode in harsh chemicals unless coated.

Stress Concentration

- Flat caps may weaken under high pressure compared to hemispherical designs.

Temporary vs. Permanent Trade-offs

- Threaded/snap caps are easy to remove but less secure for high-pressure systems.

Customization Costs

- Non-standard sizes or shapes (e.g., ellipsoidal) incur higher production expenses.

Flow Disruption Risk

- Improperly fitted caps can create turbulence or debris traps in pipelines.

Maintenance Access

- Permanent welded caps hinder quick inspections or cleaning without cutting.

How are Pipe Caps made

- Material Selection

- Metals (e.g., stainless steel, carbon steel, alloy steel): Chosen for high-pressure, high-temperature, or corrosive environments.

- Plastics (e.g., HDPE, LDPE, PVC): Selected for lightweight, chemical-resistant, or low-cost applications.

- Forming Techniques

- Forging: Heated metal billets are pressed into shape for high-strength caps (common in oil and gas).

- Casting: Molten metal or plastic is poured into molds for cost-effective production of standard sizes.

- Machining: CNC machines carve caps from solid blocks for custom dimensions or tight tolerances.

- Surface Treatment

- Coatings (e.g., galvanizing, epoxy) or passivation (for stainless steel) to enhance durability.

- Polishing for sanitary applications (e.g., food, pharmaceuticals).

- Quality Control

- Hydrostatic testing to verify pressure resistance.

- Dimensional checks (OD, thickness) and visual inspections for defects.

What is the purpose of a Pipe Cap

End Sealing

Close open pipe ends during maintenance, transport, or decommissioning to prevent leaks.Contamination Prevention

Block debris, moisture, or chemical ingress in storage or inactive pipelines.Pressure Management

Contain internal pressure in pressurized systems (e.g., oil/gas, HVAC) during testing or operation.Corrosion Protection

Shield pipe interiors from environmental exposure (UV, moisture, chemicals).Safety Compliance

Eliminate hazards from open pipes in industrial or public spaces.Temporary Closure

Allow easy access for inspections or cleaning with removable designs (threaded, snap-on).Custom Applications

Adapt to specialized needs like sanitary finishes (food/pharma) or insulated layers (thermal/acoustic).

Our Pipe Cap Dimensions and Material

| Outside Diameter | 21.3 to 2032 mm (1/2″ to 80″ NPS) | |

| Wall Thickness | 2.11 to 60 mm (SCH10 to XXS) | |

| Type | Butt welded, socket welded, threaded, flanged | |

| Material Grade | A/SA-234 | WPB, WPC, WP1, WP11, WP12, WP22, WP5, WP9, WP91, etc. |

| A/SA-420 | WPL6, WPL9, WPL3, WPL8 | |

| A/SA-403 | WP304, WP304H, WP304L, WP310, WP316, WP316H, WP316L, WP317, WP321, WP347, etc. | |

| A/SA-815 | S31803, S32205, S32750, S32760, S32950, S39274, S32550, etc. | |

| A-860 | WPHY 42, WPHY 46, WPHY 52, WPHY 60, WPHY 65, WPHY 70 | |

For other customized requirements, please contact us.

What is the Pipe Cap Price

Please contact our sales manager Allen@sanesteel.com

Why Choose Us

- a 16-year pipe cap supplier. We are experts.

- solutions for all your needs

- the highest product quality

- the low lead times

- excellent customer service