What are Integral Low Finned Tubes

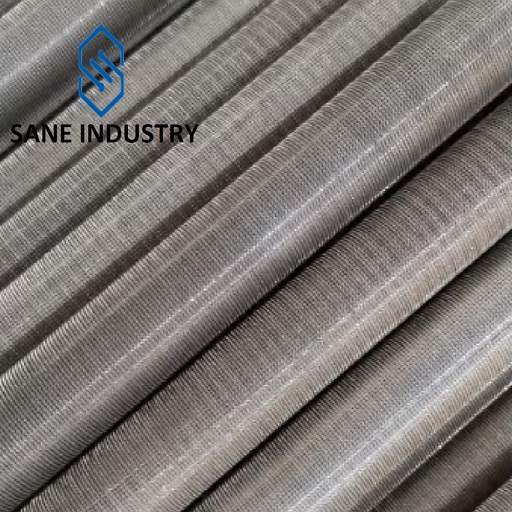

Integral low finned tubes represent a specialized category of heat transfer components that combine the benefits of traditional low fin tubes with enhanced performance characteristics through their unique manufacturing process. These fin tubes feature external low fins that are integrally formed with the base tube material, creating a single-piece construction that offers superior thermal conductivity and mechanical strength compared to standard low finned tubes where fins are separately attached.

The term “low fins” in this context refers specifically to the short height of these extended surfaces, typically ranging from 0.2mm to 1.5mm in height, with fin densities that can reach up to 42 fins per inch (FPI). This high fin density combined with the low fins create an optimal balance between surface area enhancement and fluid flow characteristics, making integral low finned tubes particularly effective for applications requiring compact, high-efficiency heat exchangers. The design of low fins allows for effective heat exchange while minimizing pressure drop and fouling issues that can occur with higher fin configurations.

The Key Features of Integral Low Finned Tubes

Structure:

- Base Tubes: Low finned tubes can be manufactured from various materials including carbon steel, stainless steel, copper, aluminum, and alloys, depending on the application requirements.

- Low Fins: As the name suggests, low fins have a relatively short height compared to other fin types. This low fins profile (typically under 1.5mm) provides an optimal balance between surface area increase and fluid flow characteristics.

Fin Attachment Method:

- The low fins are formed as an integral part of the base tube through extrusion or embedded process, eliminating the thermal interface resistance found in separately attached fin designs. This results in heat transfer coefficients that are 20-30% higher than conventional low fin tubes.

The Manufacturing Process of Integral Low Finned Tubes

Material Preparation

- Base tubes are typically made of ductile metals such as copper, aluminum, carbon steel, or stainless steel.

- Material choice depends on thermal conductivity, corrosion resistance, and application requirements.

Extrusion Process

- Extrusion Die Setup: A precision die with the desired fin pattern is installed in the extrusion machine.

- Extrusion Operation: The tube is forced through the die, causing the material to flow outward and form the low fins as an integral part of the tube.

- Cooling and Sizing: The extruded tube is rapidly cooled to set the fin geometry and then passed through sizing dies to ensure dimensional accuracy.

Embedded Fin Process

- Grooving: Precision grooves are machined into the base tube at the desired fin locations.

- Fin Formation: The tube is then rolled or pressed to form low fins that are mechanically locked into the grooves.

Both processes result in low fins that are metallurgically bonded to the base tube, providing excellent thermal conductivity and resistance to mechanical damage. The choice between methods depends on factors such as material type, production volume, and specific performance requirements.

The Advantages of Integral Low Finned Tubes

Superior Thermal Conductivity

The elimination of the fin-to-base interface resistance results in heat transfer coefficients that are 20-30% higher than standard low fin tubes.Enhanced Mechanical Strength

The integral low fins construction provides significantly better resistance to mechanical damage during handling, installation, and operation. This is particularly important in applications involving vibration or thermal cycling.Improved Fouling Resistance

The smooth transition between low fins and base tube reduces areas where fouling materials can accumulate, leading to longer maintenance intervals and improved long-term performance.Higher Fin Efficiency

Due to the excellent thermal contact between low fins and base tube, integral low finned tubes maintain fin efficiencies above 90% even at high fin densities, compared to 80-85% for standard designs.Consistent Performance

The precision manufacturing process ensures uniform low fins geometry across the entire tube length, eliminating the performance variations that can occur with separately attached fins.- Cost-Effectiveness

Low fin tubes typically offer a better cost-to-performance ratio than high finned tubes, providing significant heat transfer enhancement without excessive material costs.

The Disadvantages of Integral Low Finned Tubes

Limited Material Compatibility

Low fins can only be formed from ductile metals (e.g., copper, soft steel, aluminum). Brittle alloys or hardened steels are unsuitable.Fin Height Constraints

Max fin height ≤1.5 mm due to material deformation limits, restricting surface area expansion compared to welded high-fin designs.Fluid Compatibility Issues

Low fins prone to fouling in high-viscosity fluids or slurries; narrow fin gaps trap particulates, reducing efficiency.Thermal Cycling Fatigue

Repeated heating/cooling may cause micro-cracks in cold-worked low fins, especially in corrosive environments.Higher Initial Tooling Costs

Precision rollers/dies for cold rolling require significant upfront investment for small-batch production.Reduced Effectiveness in Laminar Flow

Low turbulence in laminar regimes limits heat transfer enhancement from finned surfaces.

Sizes and Materials of Our Integral Low Finned Tubes

| Base Tube Diameter | 8 to 32 mm | 3/8″ to 1″ NPS |

| Base Tube Wall Thickness | 0.8 to 3 mm | 0.03″ to 0.12″ |

| Base Tube Length | ≤32,000 mm | ≤92 ft |

| Base Tube Material | Carbon Steel (A106B, P235GH, A179, A210, A192, etc.) Alloy Steel (P5, T5, P9, T9, T11, T22, etc.) Stainless Steel (TP304, TP316, TP347, B407 800H/HT, etc.) aluminum, copper, titanium | |

| Fin Pitch | 629 to 1653 FPM | 16 to 42 FPI |

| Fin Height | 0.2 to 1.5 mm | 0.008″ to 0.06″ |

| Fin Thickness | 0.27 to 1 mm | 0.01″ to 0.04″ |

| Fin Material | Same as base tube | |

| Fin Type | Integral low fins | |

For other customized requirements for Low Fins Tubing, please contact us.

What is the Price of Integral Low Finned Tubes

Please contact our sales manager Allen@sanesteel.com.

Our Production Capacity of Integral Low Finned Tubes

Total six low fin tube machines, monthly production capacity is 140,000 meters in total.

Applications of Integral Low Finned Tubes

HVAC Systems

Heating, ventilation, and air conditioning systems often incorporate low fin tubes in chillers and heat recovery units.Air Cooled Heat Exchangers

Low fin tubes are commonly used in air-cooled condensers and coolers where they facilitate efficient heat transfer between process fluids and ambient air.Refrigeration Systems

In refrigeration applications, low fin tubes serve as condenser and evaporator coils, providing the necessary surface area for phase change heat transfer.Power Generation

Power plants utilize low fin tubes in various heat exchangers, including feedwater heaters and condensers, to improve overall plant efficiency.Chemical Processing

The chemical industry employs low fin tubes in reactors, reboilers, and other process equipment where reliable heat transfer is critical.Corrosive Service Environments

The uniform material composition of integral low fin tubes provides better resistance to corrosion in aggressive chemical processing applications.Phase Change Applications

The excellent thermal characteristics make integral low fin tubes particularly effective for condensation and evaporation processes where maximizing heat transfer is critical.

Why Choose Us

- a 16-year low fin tube manufacturer in this industry. We are experts.

- solutions for all your low fins tubing needs

- the highest product quality

- the low lead times

- excellent customer service