What is an Extruded Finned Tube

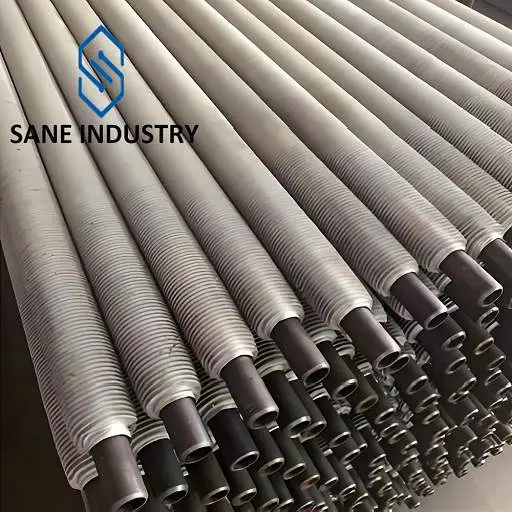

An Extruded Fin Tube, also known as aluminium extruded fin tube or bimetallic fin tube, is an advanced heat transfer component designed for efficient thermal transfer in various industrial applications. These extrudded fin tubes feature fins that are extruded from an aluminum muff tube which is closely fitted over the base tube, creating a seamless and highly conductive bond, optimizing performance in extreme thermal and corrosive environments.

The Key Features of an Extruded Fin Tube

Structure:

- Inner Tube: High-strength material (e.g., carbon steel pipes, stainless steel pipes) for structural integrity and pressure resistance.

- Outer Fins: Corrosion/abrasion-resistant metal (e.g., aluminum, copper) extruded seamlessly from the tube.

Extruded Fin Tube Manufacturing Process:

- Extruded construction: Aluminum fins are formed by extruding aluminum through a die under high pressure (around 1200 psi).

- Superior thermal contact: The cold working process creates a flawless bond between tube and fin.

The Manufacturing Process of an Extruded Fin Tube

Material Preparation

- Base Tube Selection:

Materials such as carbon steel, stainless steel (304/316), or copper are chosen for their thermal conductivity and corrosion resistance. - Aluminum Tube Matching:

Aluminum tubes (e.g., Al 6061/6063) are sleeved over the base tube, with wall thickness tolerance controlled within ±0.1 mm.

- Base Tube Selection:

Pre-Treatment

- Base and aluminum tubes undergo degreasing and acid pickling to remove oxides and contaminants, ensuring clean bonding surfaces.

Sleeving Aluminum Tube

- Aluminum and base tubes are assembled with a clearance fit (0.1–0.3 mm) and tightly sleeved using hydraulic or mechanical methods.

Extrusion Forming

- Cold/Hot Extrusion:

- Cold Extrusion: Performed at room temperature under 200–400 MPa pressure, suitable for plastic deformation of aluminum tubes.

- Hot Extrusion: Aluminum is heated to its recrystallization temperature (~350–450°C) to reduce deformation resistance.

- Mold Design:

Helical or longitudinal fin molds are used, with multi-stage forming rollers ensuring fin height precision (±0.2 mm).

- Cold/Hot Extrusion:

Quality Control

- Pull-off tests verify bonding strength (>200 MPa)

- Microscopic examination checks extrusion consistency

- Dimensional inspections ensure fin spacing tolerance

The Advantages of an Extruded Fin Tube

Monolithic Construction

- An Extruded Fin Tube’s seamless integration of fins and base tube eliminates weld points, reducing leakage risks and enhancing pressure resistance (up to 30 MPa).

High Thermal Efficiency

- Tight fin-to-tube bond and customizable fin density maximize heat transfer surface area.

Corrosion Resistance

- Uniform material composition (e.g., stainless steel, Inconel) prevents galvanic corrosion, ideal for acidic/alkaline environments.

Extreme Temperature Tolerance

- An Extruded Fin Tube withstands temperatures from -200°C to 600°C without thermal stress cracking due to homogeneous thermal expansion.

Low Maintenance Design

- Smooth, continuous fins resist fouling and abrasion in high-particulate gas/liquid flows.

Material Versatility

- An Extruded Fin Tube is compatible with aluminum, copper, titanium, and high-performance alloys for specialized applications.

Cost-Effective Longevity

- An Extruded Fin Tube is 20–30% longer service life than welded fins in aggressive industrial settings, reducing replacement frequency.

The Disadvantages of an Extruded Fin Tube

Material Restrictions

- An Extruded Fin Tube is limited to ductile metals (aluminum, copper); unsuitable for brittle alloys like titanium.

- Base tube wall thickness reduced by 15–30%, weakening high-pressure resistance.

Complex Manufacturing

- An Extruded Fin Tube requires costly precision molds, increasing tooling expenses by 40–60%.

- Energy-intensive process (20–30% higher than welding).

Fin Design Limits

- Max fin height: 20 mm (aluminum) or 15 mm (copper); higher fins risk cracking.

- High-density fins (>8/cm) weaken root strength due to stress concentration.

Efficiency Loss

- Micro-gaps at fin-base interface raise thermal resistance by 10–15%.

- Tight fin spacing (<3 mm) traps dust, cutting efficiency by 25% over time.

Maintenance Challenges

- Damaged fins require full tube replacement; no in-situ repair.

- Coatings peel at fin roots, accelerating corrosion.

Cost & Sustainability Issues

- 5–8% scrap rate during production.

- Mixed-material designs hinder recycling (e.g., aluminum/steel).

Sizes and Materials of Our Extruded Finned Tubes

| Base Tube Diameter | 19 to 60.3 mm | 3/8″ to 2″ NPS |

| Base Tube Wall Thickness | 0.5 to 4 mm | 0.02″ to 0.16″ |

| Base Tube Length | ≤32,000 mm | ≤92 ft |

| Base Tube Material | Carbon Steel (A106B, P235GH, A179, A210, A192, etc.) Alloy Steel (P5, T5, P9, T9, T11, T22, etc.) Stainless Steel (TP304, TP316, TP347, B407 800H/HT, etc.) aluminum, copper | |

| Fin Pitch | 78 to 472 FPM | 2 to 12 FPI |

| Fin Height | 5 to 16 mm | 0.19″ to 0.63″ |

| Fin Thickness | 0.3 to 1.2 mm | 0.01″ to 0.05″ |

| Fin Material | aluminum, copper | |

| Fin Type | Extruded | |

For other customized requirements for an Extruded Fin Tube, please contact us.

What is the Price of Extruded Finned Tubes

Please contact our sales manager Allen@sanesteel.com.

Our Production Capacity of Extruded Finned Tubes

Total twelve extruded fin tube machines, monthly production capacity is 150,000 meters in total.

Extruded Fin Tube Uses

Power Generation

- Air-Cooled Condensers: In power plants, extruded aluminium finned tubes are used in large air-cooled condensers to reject waste heat to the atmosphere.

- Boiler Economizers: Extruded aluminium finned tubes improve boiler efficiency by preheating feedwater using waste heat from flue gases.

- Transformer Cooling: Extruded aluminium finned tubes are used in oil-cooled transformers to dissipate heat generated during operation.

Chemical and Petrochemical Processing

- Process Heat Exchangers: Extruded aluminium finned tubes handle corrosive fluids in chemical plants, often made from stainless steel or special alloys.

- Reactor cooling systems: Extruded aluminium finned tubes provide precise temperature control and reduce fouling rates by up to 40% compared to smooth fin designs.

- Distillation columns: Extruded aluminium finned tubes improve separation efficiency with compact heat exchanger designs.

Oil & Gas

- Refinery heat exchangers: Extruded aluminium finned tubes perform well with viscous fluids, offering corrosion resistance in stainless steel variants.

- LNG processing equipment: Extruded aluminium finned tubes are suitable for cryogenic applications with bimetallic (steel/aluminum) construction.

HVAC and Refrigeration Systems

- Air Conditioning Coils: Extruded aluminium finned tubes are widely used in evaporators and condensers due to their excellent heat transfer properties and corrosion resistance.

- Refrigeration Systems: Extruded aluminium finned tubes are used in both commercial and industrial refrigeration units for efficient heat exchange between refrigerant and air.

- Heat Recovery Ventilators: Extruded aluminium finned tubes help recover energy from exhaust air streams in energy-efficient buildings.

Transportation

- Automobile Radiators: Extruded aluminium finned tubes are common in modern vehicle cooling systems.

- Aircraft Heat Exchangers: Extruded aluminium finned tubes are used in environmental control systems due to their lightweight and high efficiency.

- Shipboard Cooling Systems: Extruded aluminium finned tubes handle seawater cooling in marine applications, often with corrosion-resistant materials.

Comparison with Other Fin Tubes

| Type | Structure | Best For |

|---|---|---|

| Bimetallic Extruded Fin Tube | Dual-metal, seamless bond | Corrosive + high-pressure |

| Single-Metal Extruded Fin Tube | Single-material fins/tube | Non-corrosive, high-temperature |

| G-Type Embedded Fin Tube | Mechanically embedded fins | Abrasive, high-vibration |

| Welded Serrated Fin Tube | Welded serrated fins | Dust-heavy environments |

Why Choose Us

- a 16-year aluminium extruded fin tube manufacturer. We are experts.

- solutions for all your fin tube needs

- the highest product quality

- the low lead times

- excellent customer service