A finned tube is a heat-transfer tube enhanced with metal fins to boost surface area and improve thermal efficiency. It’s widely used in heat exchangers, HVAC systems, boilers, and industrial cooling units. Finned tubes offer higher heat-transfer performance, reduced energy use, and compact design. They’re essential in power plants, petrochemical facilities, refrigeration, and waste-heat recovery applications.

At SANE INDUSTRY, we’ve been involved in the world of finned tubing for over 16 years, connecting businesses across more than 20 countries with the premium finned tubes they need. We noticed that many engineers and buyers search for clear, practical information when choosing finned tubes, but the details can feel overwhelming.

That’s why we wrote this guide – to break things down in a way that’s easy to follow, even if you’re not deeply technical. Let us walk you through everything you need to know about finned tubing – from how it works, its advantages and applications to how to determine the perfect finned tube type for your next project.

What Is a Finned Tube?

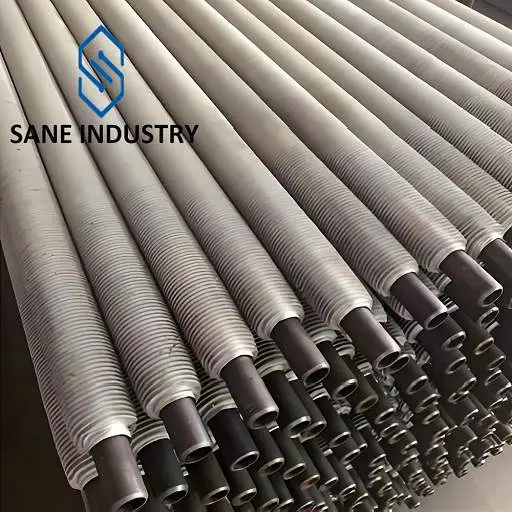

So what’s a finned tube, you ask? Finned tubes(also known as fin tubes or finned pipes in technical terminology) are specialized heat-exchange components designed to amplify thermal efficiency by extending the surface area of base tubes through attached fins. This innovation transforms ordinary tubes into high-performance heat exchangers, making them indispensable across industries ranging from energy production to HVAC systems. Their core functions include reducing contact thermal resistance and providing corrosion and wear resistance, making fin tubes commonly used in waste heat recovery and heat exchange equipment.

What Makes Up a Finned Tube? Key Parts & Structure

Structurally, finned tubes consist of two main parts: the base tube and the fins.

- Base Tube: The base tube serves as the channel for heat medium flow, typically made of materials such as carbon steel pipes, stainless steel pipes, or copper pipes.

- Fins: The fins are metal components attached to the outer surface of the base tube via welding, extrusion, or mechanical bonding; common shapes include spiral fins, longitudinal fins, and serrated fins. These geometries increase surface area by 5–10x compared to smooth tubes. Common materials are stainless steel, carbon steel, aluminum, and copper.

A finned tube bundle, composed of multiple finned tubes arranged in a certain pattern, forms the basic unit of a heat exchanger.

How Does a Finned Tube Work? Step-by-Step Guide

Finned tubes work by increasing the surface area for heat exchange between a fluid (liquid/gas) inside the tube and the surrounding medium (e.g., air). The fins act as extended surfaces, improving thermal efficiency by conduction and convective heat transfer. Below are the key steps in operation:

- Fluid flows inside the base tube: Hot/cold fluid (such as water, steam or oil) enters the base tube.

- Heat is conducted through the tube wall: Hot/cold fluid transfers heat to/from the tube wall.

- Heat conduction to fins: Since the fins are tightly connected to the base tube and are typically made of materials with good thermal conductivity, heat from the tube wall can quickly transfer to the fins.

- External Heat Exchange: Fins dissipate/absorb heat from the external environment (e.g., air) through forced or natural convection.

The key role of fins is to significantly increase the surface area in contact with the surrounding air. Heat is exchanged between the fins and the air, which absorbs heat and increases in temperature. The heated air naturally rises, and cooler air from the surroundings replaces it, forming a natural air convection cycle. This convective process continuously transfers heat to a broader area, raising the ambient temperature.

What Are The Common Types of Finned Tubes?

Finned tubes come in different types based on material, fin design, and manufacturing method. Understanding the distinctions helps you choose the right tube for your system. Below, we break down the most common categories.

- Finned Tube Types by Manufacturing Process

| Finned Tube Type | Structure | Manufacturing Process | Examples |

| Welded Fin Tube | Fins attached to the base tubes via welding | High-frequency welding(HFW), Medium frequency welding, Laser welding | HFW Serrated Fin Tube, Longitudinal Fin Tube, H Type Fin Tube, Laser Welded Fin Tube |

| Embedded Fin Tube | Fins mechanically bonded into grooves on the tube surface | Groove machining + fin insertion | G Type Embedded Fin Tube |

| Extruded Fin Tube | Fins formed by extruding the base tube material into fin shapes | Cold extrusion | Extruded Fin Tube, Integral Low Fin Tube, Integral High Fin Tube |

| Tension-Wound Fin Tube | Fins mechanically wrapped around a base tube | Tension-Wound | L, LL, KL-Foot Fin Type Fin Tube |

- Finned Tube Types by Fin Shape

| Fin Tube Type | Description | Characteristics |

| Solid Fin Tube | The most widely used basic type, featuring simple solid metal strips uniformly distributed on the base tube surface | low manufacturing cost, easy to clean, uniform heat transfer area extension, relatively low airflow resistance |

| Corrugated Fin Tube | Metal strips are pressed into wavy patterns | increases heat transfer area by 15%-20%, wavy structure enhances turbulence but with slightly higher airflow resistance than solid fins |

| Serrated Fin Tube | fins with serrated notches | combines extended heat transfer area with enhanced disturbance, better heat transfer performance than corrugated fins but with increased resistance |

| Longitudinal Fin Tube | Fins run parallel to the tube axis | enhances heat transfer through increased surface area and defined flow channels, lower flow resistance and easier maintenance, less effective in creating turbulence |

| Plate Fin Tube (H Fin Tube) | H-shaped fin arrangement | forms dual flow channels to enhance heat transfer efficiency through optimized turbulence and surface area |

- Finned Tube Types by Material

| Finned Tube Type | Key Characteristics | Typical Applications |

| Carbon Steel Finned Tube | Low cost, high strength, but poor corrosion resistance; requires surface treatment (e.g., galvanization) for extended lifespan | Industrial boilers, HVAC systems, and other medium-low temperature environments |

| Stainless Steel Finned Tube | Excellent corrosion resistance (especially 304/316L), good high-temperature stability, but higher cost | Chemical processing, food industry, marine environments, and other corrosive conditions |

| Copper Finned Tubing | Exceptional thermal conductivity (~400 W/m·K), easy to process, but expensive and lower strength | Precision instruments, refrigeration equipment, and other high-efficiency heat transfer applications |

| Aluminum Finned Tube | Lightweight, good thermal conductivity (~237 W/m·K), moderate cost, but poor high-temperature and corrosion resistance | Automotive radiators, electronic cooling, and other lightweight scenarios |

| Composite Metal Finned Tube | Combines advantages of different materials (e.g., copper-aluminum), balancing cost and performance, but complex manufacturing process | Specialized heat transfer needs (e.g., new energy battery thermal management) |

What Are Finned Tubes Used For?

Finned tubes are widely used across industries due to their efficient heat exchange:

- Petrochemical Industry

In refineries and chemical plants, finned tubes are extensively used in reboilers, condensers, and reactor temperature control systems. A large petrochemical project using spiral fin tubes achieved a 40% increase in heat exchange efficiency and a 25% reduction in equipment size.

- Power and Energy Systems

Gas turbine waste heat boilers use high-frequency welded fin tubes to reduce exhaust gas temperatures, achieving a heat recovery rate of over 75%. A power plant retrofit case showed that using stainless steel finned tubes extended boiler life to 15 years. In the nuclear power sector, titanium alloy finned tubes are used for seawater cooling systems, with corrosion resistance tripling maintenance cycles. In thermal power plants, cold-wound fin tubes are used as economizers and air preheaters in boilers.

- Metallurgical Industry

Finned tube heat exchangers for blast furnace hot blast stoves can withstand 1200°C high-temperature flue gas, preheating combustion air to over 800°C. A steel enterprise using composite fin tubes reduced energy consumption per ton of steel by 8%. The oil cooling system in rolling mill production lines uses copper-aluminum composite fin tubes, achieving oil temperature control precision within ±2°C.

- Construction and Civil Applications

In the construction sector, finned tube radiators are mainly used in HVAC and ventilation systems for large commercial buildings, data centers, and factory workshops. Steel finned tube radiators, with fins installed on the outside of steel pipes, significantly increase the heat dissipation area, quickly reaching the set temperature in indoor spaces, making fin tubes ideal for large areas with high heating efficiency requirements.

- New Energy Field

With the development of new energy technologies, finned tubes are increasingly used in solar and wind energy applications. In solar water heaters, large-diameter finned tubes serve as core components, with their efficient heat exchange properties enabling higher solar energy utilization and faster heating rates. In geothermal energy conversion systems, large-diameter finned tubes are used to extract geothermal energy and convert it into heat.

5 Key Advantages and Benefits of Finned Tubes

- Efficient Heat Dissipation: By increasing fins on the finned tube surface, the heat dissipation area is significantly expanded, improving heat dissipation efficiency. Fins allow heat to transfer more quickly from the base tube to the air.

- Excellent Corrosion Resistance: The hot-dip galvanizing process forms a dense zinc layer on the finned tube surface, providing outstanding corrosion resistance by effectively isolating air and moisture.

- Superior Pressure Resistance: The high strength and toughness of steel give finned tubes excellent pressure resistance, making them suitable for heating systems at various pressure levels.

- Good Space Adaptability: Fin tubes are available in various specifications and shapes, they can be flexibly adjusted during installation to meet different spatial layouts and usage requirements.

- Relatively Long Service Life: The durability of steel itself, combined with the corrosion-resistant treatment processes used during finned tube production, provides good corrosion resistance.

Disadvantages and Limitations of Finned Tubing

- Higher Cost: The production cost of hot-dip galvanized finned tubes is relatively high due to their complex manufacturing processes and high material quality requirements.

- Susceptibility to Corrosion and Rust: Despite corrosion protection measures, fin tubes are prone to corrosion and rust in heating systems with high oxygen content or poor water quality.

- High Water Quality Requirements: The pH, oxygen content, and impurities in the water must be controlled within certain limits, otherwise corrosion will accelerate.

- Higher Maintenance Costs: Regular maintenance is required, and once corrosion or damage occurs, repairs are more difficult.

- Limited Fin Spacing: In certain specific applications, larger fin spacing may be required to meet heat dissipation needs.

Future Trends & Innovations of Finned Tubes

Finned tube technology is evolving towards higher efficiency, lighter weight, and smarter applications:

- Material Innovation

The industry focuses on developing efficient lightweight materials, using high-frequency welding and laser welding technologies to improve product lifespan and production efficiency. Galvanized finned tubes gain overall corrosion resistance through the galvanizing process, with material selection, fin bonding processes, and galvanizing technology jointly determining equipment performance.

- Process Improvement

High-frequency weldded finned tubes use 200-500 kHz high-frequency current to fuse fins to the base tube, offering high bonding strength with uniform zinc coating coverage during galvanizing. The application of laser welding technology further improves the connection quality between fins and base tubes, reducing contact thermal resistance.

- Structural Optimization

3D printed variable cross-section finned tubes can automatically adjust fin density based on fluid distribution, with tests showing a 28% reduction in pressure drop and a 17% increase in heat transfer. New structures like split fins, narrow-wide alternating variable channel cross-section honeycomb fins optimize heat contact area and fluid distribution, improving heat transfer efficiency by 20%-40%.

- Expansion of Application Areas

With advancements in materials science and manufacturing processes, finned tubes will expand into new areas such as miniaturization (e.g., chip cooling) and extreme environments (e.g., deep drilling). In emerging fields like new energy vehicle battery thermal management and data center cooling, finned tube technology will play an even greater role.

Finned Tube vs Plain Tube – Key Differences at a Glance

| Factor | Finned Tube / Finned Pipe | Plain Tube / Bare Tube |

| Heat-Transfer Efficiency | High (Dramatically higher due to increased surface area, often 5x to 20x better). | Standard (Limited by the bare tube circumference). |

| Surface Area | Very Large (Fins provide a massive external area for heat exchange). | Smallest (Only the area of the cylindrical tube wall). |

| Best For | Gas-to-Liquid or Gas-to-Gas transfer (High efficiency required where one fluid has a low heat transfer coefficient). | Liquid-to-Liquid transfer (Where both fluids have high heat transfer coefficients). |

| Performance in Air | Excellent (The standard choice for air cooling/heating applications like HVAC and air coolers). | Poor (Requires excessive length to achieve adequate heat transfer with air). |

| Performance in Liquids | Limited Advantage (Fins offer little benefit when transferring heat between two high-density liquids). | Excellent (Standard choice where the primary heat transfer barrier is the tube wall, not the external fluid). |

| Energy Efficiency | High (Achieves required duty with less material, reducing pump/fan energy use in the overall system). | Lower (Requires larger components, potentially leading to higher pumping/fan power consumption). |

| Space Requirements | Compact (Fewer tubes required for the same job, leading to a smaller, lighter heat exchanger). | Bulky (Requires a much larger footprint or length to achieve equivalent heat duty). |

| Cost Range | Higher (Higher initial unit manufacturing cost due to specialized processes like welding or extrusion). | Lower (Simple, lower-cost material). |

| Cleaning | More Difficult (Fins trap deposits; requires specialized methods like pressure washing or air lancing). | Easy (Simple brushing or chemical flush). |

| Durability | High (Especially welded types resist thermal cycling, but fins are susceptible to physical damage). | Very High (Only susceptible to corrosion or internal pressure failure). |

| Weight | Lighter (Lower total weight for the equivalent heat load due to smaller unit size). | Heavier (Greater material volume required for the equivalent heat load). |

| Applications | Power plants, HVAC, Air Coolers, Economizers, Process Heaters. | Shell & Tube Exchangers, Boilers (fire-side), Piping Networks, Simple Condensers. |

Factors to Consider When Choosing the Right Finned Tube for Your Needs

- Identify Operating Conditions and Requirements

- Medium Characteristics: Choose materials based on corrosiveness, viscosity, and temperature (e.g., stainless steel for corrosion resistance, copper alloys for high thermal conductivity). High-temperature environments require heat-resistant materials (e.g., titanium alloys).

- Flow Rate and Pressure: Larger flow rates require larger tube diameters, while high-pressure environments demand designs with higher pressure resistance.

- Thermal Load and Space Constraints: High thermal loads require optimized fin height/spacing; limited spaces call for compact designs.

- Key Parameter Design

- Fin Height: Increases heat dissipation area but may increase air resistance—balance efficiency and energy consumption.

- Fin Spacing: Narrow spacing improves heat transfer but may accumulate dust; wider spacing is easier to clean.

- Tube Diameter and Wall Thickness: Larger diameters reduce fluid resistance, while thicker walls enhance pressure resistance.

- Material and Process Selection

- Materials: Corrosive media: Stainless steel or titanium alloys. Thermal conductivity needs: Copper or aluminum alloys.

- Welding Processes: Laser welding offers high strength and minimal deformation, ideal for high-pressure/high-temperature applications.

- Fin Type and Structure

- Longitudinal/Transverse Fins: Choose based on fluid flow direction. Transverse fins (e.g., spiral, corrugated) enhance turbulence and heat transfer efficiency.

- Special Designs: Corrugated or spiral fins increase surface area but at higher cost.

- Cost and Supplier Evaluation

- Cost-Effectiveness: High-performance materials or complex designs may increase initial costs. Therefore, it is necessary to comprehensively consider both the initial investment and the long-term maintenance expenses.

- Supplier Qualifications: Select vendors with strict quality control and after-sales support.

- Application-Specific Adaptations

- Petrochemical/Power: High-temperature, high-pressure designs (e.g., high-frequency welded fin tubes).

- Heating Systems: Steel fins for pressure resistance, copper for corrosion resistance.

- New Energy: Micro-fin tubes for hydrogen liquefaction or data center liquid cooling.

Top 10 Recommended Finned Tube Options and When to Use Each Type

Finding the right finned tube can feel overwhelming because each type is built for a specific purpose. To make things easier, here’s a clear, practical breakdown of the most reliable finned tube options – and when each one is worth considering.

1. High Frequency Welded Solid Finned Tubes

These High Frequency Welded Solid Finned Tubes are built for heavy-duty industrial performance. The fins are welded directly to the base tube using high-frequency welding, creating a solid, durable bond. They handle high pressures and high temperatures extremely well, making them ideal for the energy and power sectors.

Best for: Power plants, waste heat recovery units, refinery heat exchangers.

Why it’s a top pick: Extremely strong metallurgical bond + exceptional durability.

2. High Frequency Welded Serrated Finned Tubes

If your priority is maximum heat transfer in air-side applications, serrated fin tubes are the way to go. The serrations break up airflow, increase turbulence, and dramatically boost heat exchange efficiency.

Best for: Air-cooled heat exchangers, gas coolers, industrial cooling units.

Why it’s a top pick: The best option for boosting thermal performance on the air side.

3. G Type Embedded Finned Tubes

If you’re dealing with high temperatures or demanding thermal cycling, G-Type embedded fin tubes are one of the safest choices. The fins are mechanically locked into grooves on the tube, which ensures excellent thermal contact and long-term stability. These are especially dependable for boilers, petrochemical heaters, and high-stress heat exchangers.

Best for: Harsh environments, high-temperature heating systems, long operating cycles.

Why it’s a top pick: Outstanding mechanical strength + long service life.

4. Extruded Finned Tubes

Aluminium Extruded Fin Tubes are perfect if you want a highly durable, corrosion-resistant, low-maintenance solution. An aluminum sleeve is extruded and bonded tightly to the tube, giving it a seamless, smooth finish. Because fouling is minimal, these fin tubes remain efficient for years with little upkeep.

Best for: HVAC systems, seawater cooling, corrosive atmospheres, air coolers.

Why it’s a top pick: Superior corrosion resistance + excellent fin bonding.

5. L, LL & KL Finned Tubes

L, LL & KL Fin Tubes’ mechanically wrapped fins are great when you want an efficient and cost-effective solution without going for full welding or extrusion. The L-foot and LL-foot designs provide solid fin coverage and decent thermal performance at a friendly price point.

Best for: Medium-temperature applications, air heaters, general-purpose heat exchangers.

Why it’s a top pick: Budget-friendly, reliable, and easy to source.

6. Laser Welded Finned Tubes

Laser welding gives incredibly precise, clean fin-to-tube bonding with minimal heat distortion. If you’re developing or maintaining modern, high-efficiency thermal systems, this is one of the most advanced finned tube technologies you can choose.

Best for: High-performance heat exchangers, precision cooling systems, advanced industrial applications.

Why it’s a top pick: High accuracy + excellent longevity + low distortion.

7. Longitudinal Finned Tubes

For applications where pressure drop must be kept low, longitudinal finned tubes are ideal. The fins run parallel to the tube instead of spiraling around it, allowing smoother airflow and reducing drag.

Best for: Economizers, flue gas heat recovery, boilers, air preheaters.

Why it’s a top pick: Delivers strong thermal performance with minimal pressure loss.

8. Finned Copper Tubing

Copper finned tubing is all about maximum conductivity. If heat transfer efficiency is your priority – especially in compact systems – copper is extremely hard to beat. It’s widely used in refrigeration, HVAC evaporators, and situations where thermal performance must stay consistently high.

Best for: Refrigeration coils, HVAC evaporators, low-corrosion indoor systems.

Why it’s a top pick: Best-in-class thermal conductivity.

9. Integral Low Finned Tubes

Integral fins are formed directly from the tube itself – no separate fin material is added – which means zero risk of fin detachment and excellent mechanical integrity. Low fin versions give you flexibility depending on how much surface area you need.

Best for: Refrigeration, compact exchangers, applications requiring leak-proof construction.

Why it’s a top pick: One-piece design = excellent reliability + long service life.

10. H Finned Tubes

H-finned tubes (also called double H-fin tubes) are excellent for dusty, dirty, or high-fouling environments. Their shape minimizes buildup and makes cleaning easier compared to standard spiral fins.

Best for: Coal-fired boilers, biomass boilers, industrial furnaces.

Why it’s a top pick: Best suited for environments with heavy soot or particulate matter.

Finned Tube Maintenance: 5 Pro Tips for Long-Term Efficiency

Even the highest quality finned tubing requires proper care to maintain peak performance. Here are 5 expert tips for keeping your finned heat exchanger tubes running smoothly:

- Monitor Pressure Drop: An unexpected increase in pressure drop on the shell side (outside the tubes) is often the first sign of severe fouling. Establish a baseline and monitor it closely.

- Schedule Regular Cleanings: For air-cooled units, plan for scheduled cleaning using high-pressure air, water, or steam lancing. Never wait until performance tanks.

- Select the Right Cleaning Method: For light, dusty fouling, dry brushing or air blasting is sufficient. For hard deposits, chemical cleaning or hydro-blasting (high-pressure water jetting) may be necessary, but always consult with a specialist to avoid fin damage.

- Inspect for Fin Damage: Over time, physical handling or aggressive cleaning can damage fins. Damaged, bent, or corroded fins drastically reduce performance. Inspect regularly and repair or replace sections if needed.

- Control Fluid Quality: If possible, treat the fluid outside the tubes (such as flue gas or cooling water) to minimize particulates and corrosive elements. Prevention is always cheaper than cure.

Wrapping Up

Finned tubing is a quiet workhorse of modern industry, seamlessly transferring heat that powers our world. Picking the right finned tube can make a real difference in how efficiently your system transfers heat, how long it lasts, and how much energy it consumes.

At SANE INDUSTRY, we bring over 16 years of experience in manufacturing and supplying high-quality finned tubes, finned pipes, fin tubes, fin pipes and tubing solutions. With more than 100 satisfied customers across 20+ countries, we’ve seen firsthand how the right product can improve system efficiency, reduce maintenance, and save costs over time. Our commitment to quality, reliability, and customer satisfaction sets us apart in the industry.

Whether you’re upgrading an existing system or designing a new one, SANE INDUSTRY’s range of finned tubes offers durable, high-performance solutions that meet a variety of industrial and commercial needs. Our products are engineered for efficiency, longevity, and value – so you can focus on what matters most: keeping your operations running smoothly.

Ready to find the perfect finned tube solution for your next project?