What is Finned Copper Tubing

Finned copper tubing(also known as copper fin tube or finned copper tube) represents a specialized category of heat exchange components that combine the superior thermal conductivity of copper with extended surface fins to enhance heat transfer efficiency. These copper fin tubes are widely used in industrial heat exchangers, boilers, and cooling systems where high thermal performance is required. The term “finned copper tubing” refers specifically to copper base tubes equipped with external fins, while “finned tubing copper” emphasizes the copper material properties in these configurations.

The Structure of Finned Copper Tubing

- Base Tube: a smooth copper tube.

- Fins: The fins can be arranged in various patterns and configurations, including longitudinal, spiral, or helical designs, each offering distinct advantages for specific applications.

- Bonding Method: High-frequency welding, extruded, laser welding, wrapped, etc.

The Types of Finned Copper Tubing

Finned copper tubing comes in several primary types based on fin arrangement and manufacturing method:

- Longitudinal Finned Tubes: Fins run parallel to the tube axis, offering advantages in specific heat transfer applications. These finned copper tubes are commonly produced through high-frequency induction welding or roll forming processes.

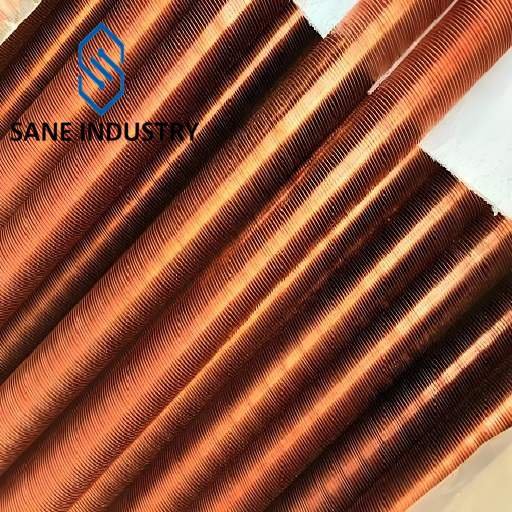

- Spiral/Helical Finned Tubes: Fins wrap around the tube in a spiral pattern, providing maximum surface area enhancement. These finned copper tubes are often created through extrusion or winding methods.

- Low Finned Tubes: These copper fin tubes are characterized by relatively short fins (typically 1-3mm high) with high fin density, optimized for applications requiring compact heat exchangers.

- High Finned Tubes: These copper fin tubes feature taller fins (up to 10mm or more) designed for applications needing significant air-side heat transfer enhancement.

- Laser Welded Finned Tubes: These copper finned tubes are manufactured using high-precision laser welding technology, which significantly enhances heat transfer efficiency.

The Manufacturing Process of Finned Copper Tubing

Finned copper tubing is manufactured through several specialized processes, each producing distinct product characteristics:

Extrusion Process

- Most common method for producing integral finned copper tubes

- Involves forcing heated copper through a die that simultaneously forms the base tube and fins

- Creates a metallurgically bonded structure with excellent thermal conductivity

Roll Forming

- Used for high finned copper tubes (fin heights over 10mm)

- Involves passing copper pipe through a series of roller dies to form fins

- Requires precise control of material microstructure and surface finish

- Enables production of complex fin geometries with tight tolerances

Winding and Welding

- Strips are helically wound around the base tube

- Joined to the tube through high-frequency induction welding or laser welding

- Allows for greater design flexibility in fin spacing and height

- Particularly suitable for large diameter finned copper tubing

Mechanical Attachment

- Fins are pressed or crimped onto the tube surface

- Often used for retrofit applications or when material combinations are required

- May introduce contact thermal resistance compared to integral methods

The Advantages of Finned Copper Tubing

Exceptional Thermal Conductivity

- Copper’s thermal conductivity is second only to silver among common metals, enabling efficient heat transfer.

Enhanced Heat Transfer Coefficients

- Finned surfaces can increase overall heat transfer rates by 2-5 times compared to bare tubes, depending on application conditions.

Optimized Airside Performance

- Fins effectively overcome the low heat transfer coefficient of air, which is typically 10-100 times lower than that of liquids.

Reduced Thermal Resistance

- Integral fin designs minimize contact resistance between fins and base tube, maintaining high efficiency.

Durability

- Copper’s natural corrosion resistance is enhanced by fin designs that promote self-cleaning through thermal expansion/contraction cycles.

Strength-to-Weight Ratio

- Copper fin tube provides excellent structural support while remaining relatively lightweight compared to steel alternatives.

Fouling Resistance

- Fin designs can incorporate features that reduce fouling, such as staggered patterns or special surface treatments.

High-Temperature Performance

- Maintains structural integrity at elevated temperatures, suitable for demanding industrial applications.

The Disadvantages of Finned Copper Tubing

Higher Cost

- Copper prices remain substantially higher than alternative materials like aluminum. This makes finned copper tubing systems 30-50% more expensive than comparable aluminum solutions.

Price Volatility

- The copper market experiences frequent price fluctuations due to geopolitical factors and supply chain disruptions, making long-term budgeting difficult for finned tubing copper system designers and finned tubing copper system manufacturers.

High-Temperature Oxidation

- When exposed to temperatures above 200°C, copper oxidizes rapidly, forming an insulating layer that significantly reduces heat transfer efficiency in applications like industrial finned tubing copper boilers.

Thermal Expansion Challenges

- With a coefficient of thermal expansion nearly 50% higher than stainless steel, finned copper tubing requires complex expansion joint designs in large systems to prevent mechanical failure.

Airside Fouling Issues

- The dense fin spacing in finned copper tubing makes it prone to accumulating particulate matter in dirty environments, requiring frequent cleaning to maintain performance.

Specialized Fabrication Requirements

- Creating high-quality copper fin tube demands expensive equipment like high-frequency induction welders or precision copper fin tube extrusion machines, limiting production to specialized copper fin tube manufacturers.

Sizes and Materials of Our Finned Copper Tubing

| Base Tube Diameter | 16 to 350 mm | 3/8″ to 14″ NPS |

| Base Tube Wall Thickness | 2 to 30 mm | 0.08″ to 1.18″ |

| Base Tube Length | ≤32,000 mm | ≤92 ft |

| Base Tube Material | Copper (C10100, C10200, C21000, C22000, C23000, C27000, C33000, C44300, C68700, C70600, etc.) | |

| Fin Pitch | 39 to 277 FPM | 1 to 7 FPI |

| Fin Height | 5 to 35 mm | 0.2″ to 1.38″ |

| Fin Thickness | 0.3 to 1.5 mm | 0.01″ to 0.06″ |

| Fin Material | Carbon Steel, 2.25Cr-1Mo, 5Cr-0.5Mo, 11-13Cr (409, 410), 18Cr-8Ni (SS 304), 25Cr-20Ni, aluminum, copper | |

| Fin Type | longitudinal, spiral/helical, low, high, laser | |

For other customized requirements for finned tubing copper, please contact us.

What is the Price of Finned Copper Tubing

Please contact our sales manager Allen@sanesteel.com.

Our Production Capacity of Finned Copper Tubing

Total two longitudinal copper fin tube machines, monthly production capacity is 50 tons in total.

Total twelve extruded copper fin tube machines, monthly production capacity is 150,000 meters in total.

Total six L, LL, KL-Foot copper fin tube machines, monthly production capacity is 180,000 meters in total.

Total two laser welded copper fin tube machines, monthly production capacity is 24,000 meters in total.

Applications of Finned Copper Tubing

HVAC and Refrigeration

- Residential/Commercial Finned Tubing Copper AC Units: As condenser and evaporator coils, where copper fin tube provides efficient heat exchange with air

- Copper Finned Tube Heat Pumps: In both air-source and ground-source configurations, enabling efficient heat transfer between different mediums

- Finned Tubing Copper Refrigeration Systems: In walk-in copper fin tube coolers, display cases, and industrial copper fin tube refrigeration units

- Finned Tubing Copper Dehumidifiers: Where efficient condensation of moisture is required

Industrial Heat Exchangers

- Power Plants: In copper fin tube condensers and copper fin tube air coolers for steam turbine systems

- Chemical Processing: For copper fin tube reactors, copper fin tube reboilers, and other copper fin tube heat exchange equipment

- Petrochemical Refineries: In various finned tubing copper heat recovery and cooling applications

- Food Processing: For pasteurization, sterilization, and cooling processes

Transportation and Automotive

- Vehicle Radiators: In both traditional and electric vehicles for engine and battery cooling

- Aircraft Systems: For hydraulic and fuel cooling applications

- Marine Applications: In engine cooling systems and HVAC for ships

Renewable Energy Systems

- Solar Thermal Collectors: As heat transfer elements in finned tubing copper solar water heating systems

- Geothermal Heat Pumps: In ground loop finned tubing copper heat exchangers

- Waste Heat Recovery: Capturing and utilizing industrial waste heat

Comparison with Other Materials

| Parameter | Finned Copper Tubing | Finned Aluminum Tubing | Finned Stainless Steel Tubing |

| Thermal Conductivity | 401 W/m·K | 237 W/m·K | 16 W/m·K |

| Corrosion Resistance | Excellent (natural) | Good (requires coating) | Excellent (passive layer) |

| Cost | Higher | Lower | Moderate |

| Formability | Excellent | Good | Moderate |

| Weight | Moderate | Light | Heavy |

| Maximum Service Temp | 200-250°C | 150-200°C | 500-600°C |

How to Choose the Right Finned Copper Tubing

When selecting finned tubing copper for an application, consider:

- Thermal Requirements: Required heat transfer rates and temperature ranges

- Environmental Conditions: Exposure to corrosive elements, moisture, or extreme temperatures

- Space Constraints: Available area for heat exchanger installation

- Fluid Characteristics: Type of working fluid and its compatibility with copper

- Pressure Ratings: System operating pressures and safety factors

Maintenance Best Practices

To ensure optimal performance and longevity of copper finned tubes:

- Regular Cleaning: Remove debris and fouling from fin surfaces using appropriate methods

- Corrosion Protection: Apply coatings or treatments in harsh environments

- Leak Detection: Monitor for signs of corrosion or mechanical damage

- Performance Monitoring: Track temperature differentials and pressure drops as indicators of condition

Why Choose Us

- a 16-year copper fin tube manufacturer. We are experts.

- solutions for all finned tubing copper prouducts

- the highest product quality

- the low lead times

- excellent customer service