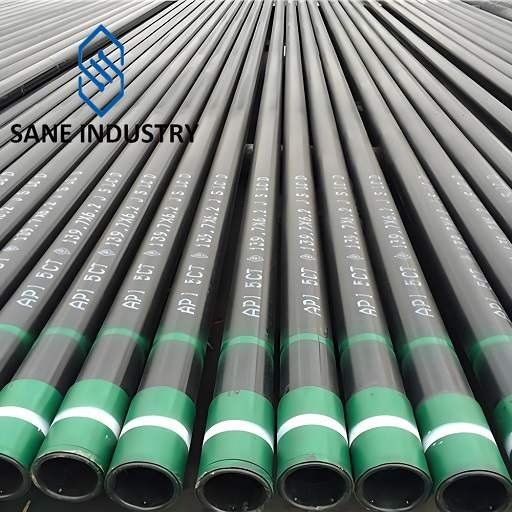

What is an API 5CT Tubing and Casing

API 5CT Tubing is a type of pipe specifically designed for use in the oil and gas industry. It serves as a crucial component in the production phase of oil and gas wells, allowing for the efficient flow of oil and gas from the well to the surface.

API 5CT Casing pipe section shape is a round, big diameter pipe put into the oil well, fixed by the cement, to protect other equipment which is mostly made of iron and steel. Oil wells shall be designed to bear the different strengths of external power, such as crush, explosion, stress, and chemical corruption. During the well drilling process, put casing into the well bore, it will stabilize the well bore perfectly.

Types of API 5CT Tubing and Casing

- Seamless API 5CT Tubing and Casing

- welded API 5CT Tubing and Casing

What are the Advantages of API 5CT Tubing and Casing

Standardization:

- Globally recognized specifications ensure compatibility and interchangeability.

- Simplifies procurement and reduces design uncertainty.

Material Performance:

- High-strength grades (e.g., P110, T95) for extreme pressure and load.

- Corrosion-resistant alloys (e.g., L80-13Cr, C90) for sour (H₂S/CO₂) environments.

Versatile Applications:

- Casing stabilizes well integrity in diverse formations (shale, sandstone).

- Tubing optimized for fluid/gas transport under high-temperature/pressure conditions.

Quality Assurance:

- Mandatory hydrostatic, NDT, and hardness testing.

- Traceability via heat numbers and mill certifications.

Cost Efficiency:

- Longevity reduces replacement frequency in harsh wells.

- ERW/Welded options lower costs for non-critical zones.

Adaptability:

- Multiple connection types (BTC, premium threads) for sealing and ease of installation.

- Customizable lengths and OD/WT combinations.

What are the Disadvantages of API 5CT Tubing and Casing

Material Limitations:

- Standard grades (e.g., J55, K55) lack corrosion resistance in severe sour (H₂S/CO₂) environments, requiring costly alloys.

- ERW (welded) types risk seam failures under extreme cyclic loads.

Environmental Challenges:

- Susceptibility to sulfide stress cracking (SSC) in Group 1 grades (e.g., P110) without strict hardness control.

- Limited high-temperature performance for non-premium connections.

Cost and Complexity:

- Premium connections (metal-to-metal seals) increase installation time and cost.

- High-grade alloys (e.g., T95, C110) raise material expenses for harsh wells.

Standardization Trade-offs:

- Fixed OD/WT combinations restrict customization for unconventional well designs.

- Thread tolerances may compromise sealing if not meticulously maintained.

Maintenance Risks:

- Weld zones in ERW casing/tubing are prone to corrosion and fatigue cracks.

- Thread galling during repeated make/break operations.

How is API 5CT Tubing and Casing made

Material Selection:

- Carbon/alloy steel billets or plates (e.g., J55, P110 grades).

- ERW types use coiled steel strips; seamless uses solid billets.

Forming:

- Seamless: Billet heated, pierced, and rolled into hollow shells via rotary/pilger mills.

- ERW: Steel strip cold-formed into cylindrical shape, welded longitudinally (electric resistance welding).

Heat Treatment:

- Quenching & tempering (Q&T) for high-strength grades (e.g., P110).

- Normalizing for corrosion-resistant alloys (e.g., L80).

End Finishing:

- Threading (BTC, LTC, or premium connections) using CNC machines.

- Beveling or coating ends for protection.

Testing & Inspection:

- Hydrostatic pressure testing (mandatory).

- NDT (ultrasonic, eddy current) for weld/seam integrity (ERW).

- Hardness, tensile, and SSC tests for sour-service grades.

Marking & Certification:

- Laser-engraved API 5CT markings (grade, size, heat number).

- Mill test reports (MTRs) for traceability.

Application of API 5CT Tubing and Casing

Well Integrity:

- Surface/intermediate/production casing stabilizes boreholes in shale, sandstone, and fractured formations.

- Prevents collapse, fluid migration, and blowouts.

Corrosive Environments:

- Grades like L80-13Cr/C110 resist H₂S/CO₂ in sour gas wells.

- T95/Q125 for high-pressure, high-temperature (HPHT) reservoirs.

Hydraulic Fracturing:

- High-strength tubing (P110, N80) withstands cyclic pressure during fracking.

- Casing isolates zones to control fluid flow.

Unconventional Wells:

- ERW casing for cost-effective shale gas/horizontal wells.

- Premium connections ensure sealing in deepwater/subsea wells.

Thermal Recovery:

- Heat-treated grades (e.g., H40, J55) for steam injection in heavy oil extraction.

- Resists thermal stress in cyclic steam stimulation (CSS).

Abandonment/Plugging:

- Temporary casing protects aquifers during drilling; retrieved post-completion.

Sizes and Materials of Our API 5CT Tubing and Casing

| Item | Casing | Tubing |

| Outside Diameter | API SPEC 5CT Table C.1 or Table E.1 | API SPEC 5CT Table C.2 or Table E.2 |

| Wall Thickness | API SPEC 5CT Table C.1 or Table E.1 | API SPEC 5CT Table C.2 or Table E.2 |

| Range length | API SPEC 5CT Table C.27 or Table E.27 | |

| Type of End | Plain-end, Short round thread, Long round thread, Buttress thread | Plain-end, Non-upset threaded and coupled, External upset threaded and coupled, Integral joint |

| Material Grade | Standard: API SPEC 5CT, API SPEC 5B, ISO 11960, etc. Grade: H40, J55, K55, N80, L80, C90, R95, T95, P110, C110, Q125, M65, any other. | |

For other customized requirements, please contact us.

Why Choose Us

- a 16-year API 5CT tubing and casing supplier. We are experts.

- solutions for all your needs

- the highest product quality

- the low lead times

- excellent customer service