Fin tubes(Finned tubes), as indispensable high-efficiency heat exchange components in modern industry, significantly enhance heat transfer efficiency by increasing the heat transfer surface area, playing a crucial role in energy, chemical, power, and other fields.

We SANE is a manufacturer of fin pipes with 16 years of experience. We are experts in the field of fin tubes. We know that many engineers and purchasing personnel do not have a comprehensive understanding of fin tubes and do not know how to select the appropriate fin tubes. That’s why we wrote this comprehensive guide-by exploring what fin tubes are, their different types, applications, and how to choose the right fin tubes, help engineers and purchasing staff gain a comprehensive and clear understanding of fin tubes.

What Is a Fin Tube?

Definition

A fin tube (also known as a finned tube, a finned pipe, a finned tubing or a fin pipe ) is a heat exchanger component designed to increase the surface area available for heat transfer between a fluid inside the tube and a surrounding fluid or air. The fins act as extended surfaces that significantly improve the heat transfer rate compared to plain tubes.

Basic Structure

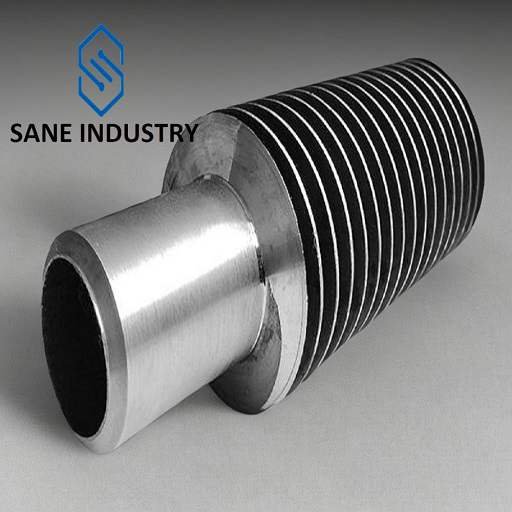

The basic structure of a fin tube consists of two primary components: the base tube and the extended fins.

- The Base Tube

The base tube of a fin tube serves as the core conduit for fluid flow, typically made from materials like carbon steel, stainless steel, or copper, depending on the application requirements.

- The Extended Fins

Attached to this base tube are the fins, which are thin metal extensions designed to maximize surface area of a finned pipe for heat transfer. These fins can be arranged in various configurations, including spiral, longitudinal, or serrated patterns, each optimized for specific thermal performance needs. The typical materials are carbon steel fins, stainless steel fins, aluminum fins, or copper fins.

- Construction Method

The construction method of fin tubes varies significantly based on their intended use. Common fin tube manufacturing processes include extrusion, where fins are formed as an integral part of the base tube; high-frequency welding, which bonds separate fins to the tube; and mechanical attachment techniques like G fin tubes and L feet fin tubes.

How Does A Fin Tube Work(Working Principle)?

- Fluid Flow Interaction

- Primary fluid (e.g., hot air) flows across the surface of a fin tube

- Secondary fluid (e.g., coolant) circulates inside the fin tube

- Temperature difference drives heat transfer

- Heat Transfer Enhancement

- Create Turbulence: Fins disrupt fluid flow, reducing boundary layers and improving convective heat transfer.

- Expand Surface Area: Fins multiply the contact area between the fin tube and fluid (air/liquid), boosting heat exchange efficiency.

- Fins conduct heat along finned length from base to tip

- Efficiency Optimization

- Fin geometry (height, spacing) is tailored for specific applications

- Material selection balances conductivity and corrosion resistance

- Attachment method of finned tubes ensures minimal thermal resistance

4 Key Performance Parameters of Fin Tubes

The performance parameters of finned tubes directly affect their heat exchange efficiency and service life, several critical parameters including:

- Fin Ratio

The ratio of the heat dissipation area of the finned tube to the surface area of the smooth tube. The fin ratio of high-frequency welded finned tubes is designed to be 5-30, expanding the heat dissipation area by 6-8 times compared to smooth tubes.

- Heat Transfer Coefficient

Combines conduction through the tube wall and convection on both sides. The heat transfer coefficient of high-frequency welded finned tubes reaches 60-300 W/(㎡・K). Under 0.6 MPa steam conditions, the heat dissipation per meter of finned tube is 450-1200 W.

- Thermodynamic Performance

Must meet the temperature, pressure, and flow rate requirements of the processed fluid. The design of finned tubing should ensure that heat can be quickly and uniformly transferred to the environment.

- Material Performance

Different materials have different thermal conductivity coefficients, mechanical strength, and corrosion resistance, requiring selection based on the application environment of finned tubes.

Classification and Types of Fin Tubes

- Fin Tube Types By Manufacturing Process

| Type | Description | Advantages | Disadvantages |

| Extruded Fin Tube | Fins are formed by extruding the base material | High mechanical strength, good thermal contact | Limited fin height options |

| Welded Fin Tube | Fins are attached to the base tube via welding | Can use different materials for fins and tube | Potential for thermal resistance at weld joints |

| G Fin Tube (Embedded Fin Tube) | Fins are mechanically embedded into grooves formed on the base tube surface | Cost-effective, easy to manufacture | Lower thermal conductivity than integral fins |

| L Fin Tube | Fins are mechanically attached to the tube | High Heat Transfer Efficiency | Corrosion Vulnerabilities in Joints |

- Fin Tube Types By Fin Geometry

| Type | Description | Typical Applications |

| Spiral Fin Tube | Fins wrap helically around the tube | Air-cooled heat exchangers, condensers |

| Longitudinal Fin Tube | Fins run parallel to the tube axis | High-velocity gas streams |

| Serrated Fin Tube | Fins with sawtooth patterns | Enhanced turbulence and heat transfer |

| Plate Fin Tube (H Fin Tube) | Flat plates attached to tubes | Compact heat exchangers |

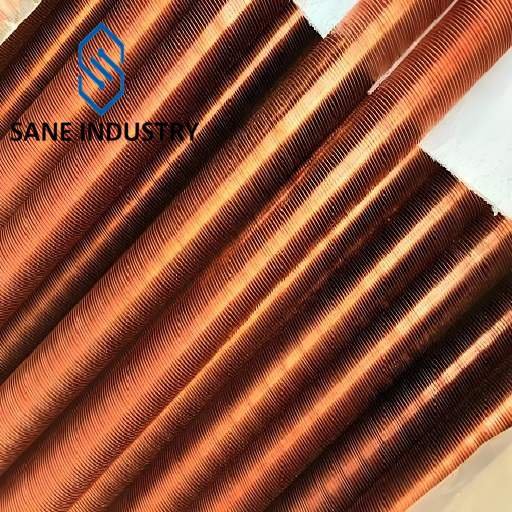

- Fin Tube Types By Material

| Material | Max Temperature | Corrosion Resistance | Cost | Common Uses |

| Carbon Steel Finned Tube | 400°C | Moderate | Low | Boilers, industrial heaters |

| Stainless Steel Finned Tube | 800°C | High | Medium-High | Chemical processing, food industry |

| Copper Finned Tubing | 200°C | Moderate | High | Refrigeration, HVAC |

| Aluminum Finned Tube | 150°C | Low | Medium | Air-cooled exchangers, automotive |

What Is The Manufacturing Process of Fin Tubes?

The manufacturing of finned tubes is a precise and complex process, including the following key steps:

- Material Preparation

Select metal materials with good thermal conductivity and mechanical strength, such as aluminum alloys, copper alloys, stainless steel, and steel. Materials must undergo strict quality inspection to ensure compliance.

- Fin Processing

Use processes such as stamping, cutting, bending, and extrusion to form fin structures with certain heights and spacings. For stainless steel-aluminum finned tubes, extrusion technology is commonly used to tightly bond aluminum fins with stainless steel tubes.

- Tube Body Processing

Use seamless steel tubes or welded steel tubes, processed through cutting, bending, and expanding to form tube structures. Special types such as spiral finned tubes also require high-frequency induction heating and rolling processes.

- Bonding Process

Connect fins to the tube body using high-frequency welding, laser welding, extruding, embedding, or mechanically attachment. Welding quality directly affects the performance and reliability of finned tubes, requiring strict control of welding parameters.

- Inspection and Testing

Include visual inspection, dimensional measurement, weld quality inspection, heat transfer performance testing, and pressure testing.

As the mainstream production method of finned tubes, the high-frequency welding process requires base tube cutting and rust removal during the base material pretreatment stage, while steel strips are cut to the specified width and leveled. During high-frequency welding, the current density can reach 3×10⁶ A/cm², completing metallurgical bonding in 0.2 seconds, with a weld shear strength of ≥180 MPa.

What Are The Advantages of Fin Tubes

Fin pipes offer superior heat transfer performance with these core benefits:

- Enhanced Heat Transfer Efficiency

- Finned tubing achieves 30-50% higher heat transfer coefficients than smooth tubes through extended surface area

- Fins disrupt boundary layers, increasing turbulence and thermal gradients

- Finned tubing particularly effective for low-conductivity fluids like air and gases

- Compact Design Advantages

- Finned tubing reduces equipment size by 30-50% for equivalent heat transfer capacity

- Finned tubing enables more compact heat exchangers in space-critical applications (e.g., automotive, aerospace)

- Finned tubing has lower system weight compared to smooth tube alternatives

- Versatile Industrial Applications

- HVAC: Finned tube improves dehumidification and energy efficiency

- Refrigeration: Finned tube enhances condenser/evaporator performance

- Power Plants: Finned tube resists corrosion in cooling towers

- Petrochemical: Finned tube withstands high temperatures/pressures

- Customizable fin geometries (height, spacing, pattern) for specific needs

- Durability and Material Benefits

- Finned tubes are available in corrosion-resistant materials (stainless steel, titanium, etc.)

- Special coatings reduce fouling and extend service life

- A finned tube withstands thermal cycling and mechanical stress better than smooth tubes

- Economic and Operational Benefits

- 10-25% lower energy consumption in HVAC systems

- Reduced maintenance frequency due to fouling resistance

- Payback period typically 1.5-3 years despite higher initial cost

What Are The Disadvantages of Fin Tubes

Fin tubes, while offering significant heat transfer advantages, also present several limitations compared to smooth tubes:

- Manufacturing Complexity

- The production process of fin pipes is more intricate than smooth tubes

- Finned tubing requires precise fin attachment methods (extrusion, welding, etc.)

- Higher defect risk due to complex geometry

- Installation Challenges

- Fin pipes are more difficult to align and fit in heat exchangers

- Finned tubing requires careful handling to avoid fin damage

- Specialized tools often needed for proper installation

- Maintenance Difficulties

- Fin pipes are harder to clean and inspect than smooth tubes

- Fins can trap debris and fouling materials

- Eddy current testing is less effective due to surface irregularities

- Performance Limitations

- Finned pipes have higher pressure drop than smooth tubes in some applications

- Finned pipes may not perform as well in extreme temperature conditions

- Fin efficiency decreases with temperature differentials

- Economic Factors

- Fin pipes are 15-40% higher initial cost than smooth tubes

- Fin pipes are more expensive to repair or replace

- Fin pipes may require more frequent maintenance in harsh environments

What Are The Industry Applications of Fin Tubes?

Fin tubes find use in a wide range of industries due to their efficiency and versatility:

- Finned tubes are used in air-cooled condensers and evaporators

- Aluminum fin tubes are common due to their light weight and good thermal conductivity

- Louvered fins enhance airside heat transfer in air conditioning units

- Power Generation

- Fin pipes are employed in boiler economizers and air preheaters

- Stainless steel fin tubes handle high temperatures and corrosive flue gases

- Spiral fin designs maximize heat recovery in limited space

- Petrochemical Processing

- Finned pipes are used in fired heaters and waste heat recovery units

- High-alloy materials resist corrosion from process fluids

- Extended surface area improves energy efficiency

- Automotive

- Fin pipe are found in radiator cores and charge air coolers

- Small, lightweight fin tubes maximize cooling in compact spaces

- Finned pipes are often made from aluminum for weight savings

- Food Processing

- Sanitary fin tubes with smooth surfaces prevent bacterial growth

- Finned tubes are used in pasteurizers and drying equipment

- Easy-to-clean designs are essential

How to Choose the Right Fin Tube for Your Application?

Selecting the optimal finned tube requires careful consideration of several factors:

- Operating Conditions

- Temperature range: Determine maximum and minimum operating temperatures

- Pressure requirements: Consider both internal and external pressures

- Fluid properties: Corrosiveness, viscosity, and fouling tendency

- Performance Requirements

- Heat transfer rate: Calculate required duty and surface area

- Space constraints: Compact designs may need high fin density

- Efficiency targets: Balance between performance and cost

- Material Selection

- Thermal conductivity: Higher conductivity materials (copper, aluminum) transfer heat better

- Corrosion resistance: Stainless steel for harsh environments

- Cost considerations: Balance performance requirements with budget

- Fin Geometry

- Fin height: Taller fins increase surface area but may reduce efficiency

- Fin density: More fins per inch improve heat transfer but increase pressure drop

- Fin pattern: Spiral, longitudinal, or louvered based on flow characteristics

- Maintenance Considerations

- Fouling potential: Choose designs that minimize deposit buildup

- Cleaning requirements: Some designs allow easier cleaning

- Lifespan expectations: More durable materials may have higher upfront costs

Plain Tubes VS. Fin Tubes

| Factor | Plain Tube | Fin Tube |

| Definition | simple cylindrical pipes without any additional surface enhancements | feature extended surfaces (fins) attached to the base tube |

| Surface Area | Minimal (only tube surface) | 2-10x greater (due to fins) |

| Heat Transfer Coefficient | Lower (especially for gases) | Higher (fins enhance turbulence) |

| Pressure Drop | Lower (smooth surface) | Higher (fins create resistance) |

| Optimal Fluid | Liquids (high thermal conductivity) | Gases (low thermal conductivity) |

| Flow Conditions | High velocity preferred | Works well at moderate velocities |

| Initial Cost | Lower (simpler construction) | Higher (more complex manufacturing) |

| Space Requirements | More (for equivalent heat transfer) | Less (compact design) |

| Maintenance | Easier to clean | Fins can trap debris |

| Longevity | More resistant to corrosion | Fins may corrode first |

| Energy Efficiency | Lower in gas applications | Higher in gas applications |

Emerging Trends in Fin Tube Technology

The finned tube industry continues to evolve with new technologies and materials:

- Nanostructured Fin Surfaces

- Enhanced surface coatings improve heat transfer

- Can increase efficiency by 10-20%

- Particularly useful in compact heat exchangers

- Additive Manufacturing

- 3D printing allows for complex fin geometries

- Enables optimized designs for specific applications

- Reduces material waste compared to traditional methods

- Hybrid Fin Designs

- Combining different fin types in one tube

- Optimizes performance for varying conditions

- Example: Spiral fins with louvered sections

- Advanced Materials

- High-performance alloys for extreme conditions

- Composite materials with tailored properties

- Graphene-enhanced coatings for improved conductivity

- Computational Fluid Dynamics (CFD) Optimization

- Digital modeling of fin performance

- Allows for virtual testing of designs

- Reduces development time and costs

Conclusion

Fin tubes(Finned tubes) are critical components in heat transfer systems across numerous industries. By understanding the different types, their characteristics, and appropriate applications, you can select the optimal finned tube for your specific needs. Whether you’re working in HVAC, power generation, or industrial processing, choosing the right finned tube design can significantly improve the efficiency and performance of your heat exchange equipment.

Remember to consider factors like operating conditions, material properties, and maintenance requirements when making your selection. As technology advances, new fin tube designs and materials continue to push the boundaries of heat transfer efficiency, offering even greater potential for energy savings and performance improvements in the future.

Should you have any further questions or requirements regarding fin tubes(finned tubes), please feel free to contact with us by email allen@sanesteel.com.